Knowledge

Widely used in the surface decoration of interior and exterior walls of large buildings and shopping malls

Product Series

Product search

Knowledge

Knowledge

Product introduction

- Categories:Knowledge

- Time of issue:2020-11-27 18:33:24

- Views:0

Description:

Information

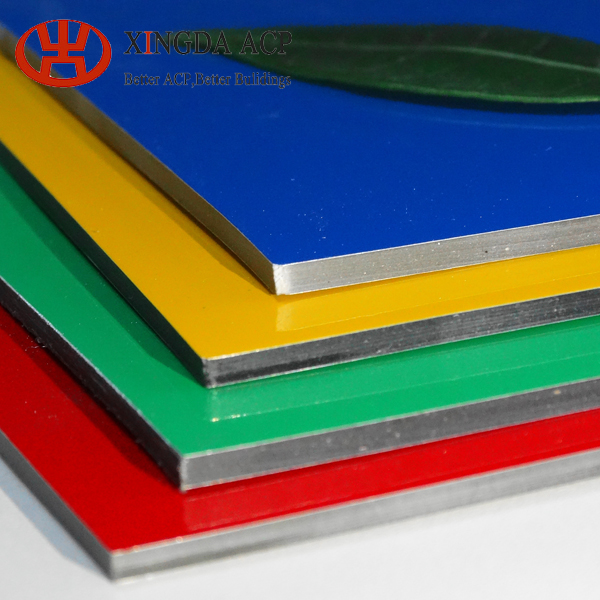

Aluminum-plastic composite panels are called as aluminum-plastic panels for short, which are new materials through a series of processes, whose surfaces are made of coating aluminum panels and cores are manufactured with polyvinyl plastic panels.

Aluminum-plastic composite panels are called as aluminum-plastic panels for short, which are new materials through a series of processes, whose surfaces are made of coating aluminum panels and cores are manufactured with polyvinyl plastic panels.

Aluminum-plastic panels were researched and produced by ALUDINGEN Company, and then improved by FORKEN and ALOCA. After 1990s, their production quality became stable gradually and reached up to a higher level.

Aluminum-plastic panels are composed by two completely different materials (metal and nonmetal). They not only retain main features of original component materials (metallic aluminum and non-metallic polyvinyl plastics) but also overcome shortcomings of original component materials. Therefore, they possess many excellent properties, such as luxuriousness, bright-colored and beautiful decoration, weather proof, corrosion resistance, impact resistance, fire protection, moisture proof, sound insulation, heat insulation, shock resistance, light weight, machine shaping, and easy movement and installation, which create wide application future for aluminum-plastic panels.

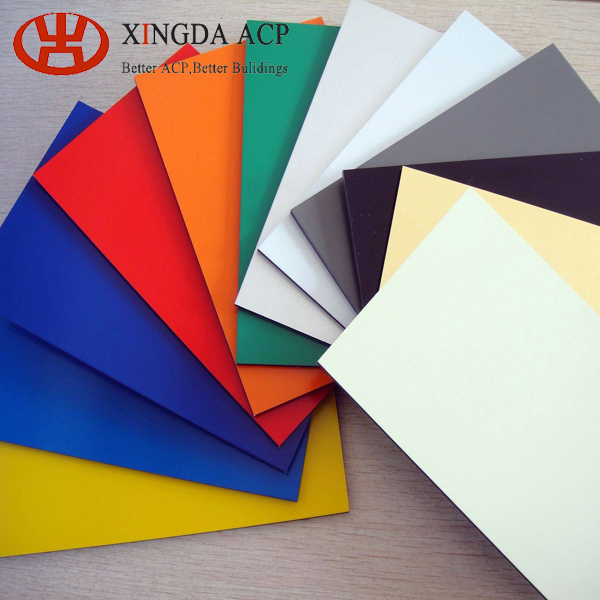

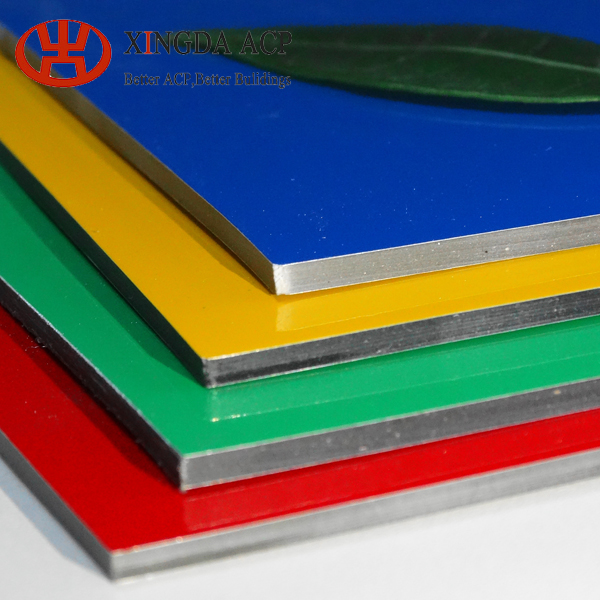

They include regular color series, colored aluminum panel series, highlight panel series, and brushed panel series.

Introductions to Xingda aluminum-plastic panels

Aluminum-plastic panels are decorative building materials for interior and exterior walls, which are the most fashionable and can embody era characteristics most after wall coating and glass curtain walls. They combine brightness of paint, mechanical behaviors of aluminum alloy, and physical and chemical properties of PE high polymer materials, with such features as light weight, high strength, inflaming retarding, sound insulation, heat insulation, bright color, and easy to be processed and shaped. Aluminum-plastic panels have become the first choice of decorative materials. Company products are detected by national authority and all indicators achieve or exceed national standards. Aluminum-plastic panels can be widely used in decorating interior and exterior walls, with rich colors which may reveal city beauty and various beautification requirements. With the use of aluminum-plastic panels of Xingda Company, buildings may be more gorgeous, luxurious, elegant, and decorative.

I. Board

In the production process, Linyi Xingda Aluminum Plastic Decorative Material Co., Ltd uses various advanced devices and strictly controls products’ dimension, precision, flatness, and thickness. Therefore, flatness on surfaces of aluminum-plastic panels is obviously superior to other building materials, and buildings with aluminum-plastic panels have integrated and smooth appearance. In addition, both surfaces of panels adopt high-strength alloy, so that their rigidity is very high and their flatness can be kept forever. And at the same time, they have extremely strong high-load bending-resistance property.

II. Surface coating

Surfaces of Xingda Aluminum Plastic products adopt fluorocarbon resin coating (KYNAR500) of PPG Company, with good brightness, strong adhesion, acid resistance, alkali resistance, corrosion resistance, pulverization resistance, and UV resistance. American PPG Company is one of fluorocarbon coatings manufacturers with the longest history, whose products have been proved to be the best in the world through application for several decades. Its products have been used in buildings for about twenty years, whose appearance is still beautiful and outdoor lifetime may be more than twenty years.

III. Core panel

Core panels in the middle of Xingda Aluminum Plastic products are made of imported PE plastics, without toxicity, covered with aluminum levels on both sides which are difficult to be burnt. It is a kind of safe fire-proof material and completely meets fire protection requirements in Building Law. Fire-proof aluminum-plastic panel core materials are the most advanced fire-proof master batch magnesium hydroxide, whose properties meet the flame-retardant level specified in GB8624-1997 Regulation.

IV. Adhesion property

In the production process of aluminum-plastic panels, the most complicated process is binding of aluminum panels and plastics. If binder quality is unstable or products are molded twice or more, products’ peel strength may not be strong enough or products may break away after one to two years or when meeting larger loads; Xingda aluminum-plastic panels adopt high polymeric membrane binder at high temperature, imported from Korea, and aluminum panels and plastics composite through high polymeric membranes. Therefore, their peel strength is high, to 180N/2.5cm, which is much higher than other joint-ventured panels and the same as imported panels.

V. Quality assurance

Xingda aluminum-plastic panels pass detection of National Building Material Testing Center according to ASTM standards, and all indicators achieve or exceed imported products of the same kind.

Scan the QR code to read on your phone

Tel:Mr. Dai 86-13869983858 86-539-8559077

Fax:86-539-8559177

E-mail:371340116@qq.com

Web:www.xingdals.com

Address:Lizhuang Town Industrial Park, Tancheng County, Linyi City, Shandong Province

Mobile site

Mobile site

底部留言

Description:

底部留言

Copyrignt ©2020 Linyi Xingda Aluminum Plastic Decorative Material Co., Ltd